We specialize in providing product design & development services, with our expertise in electronics hardware design, mechanical design and design validation. With our comprehensive and seamless approach, we transform your product ideas into reality, delivering exceptional quality and outstanding outcome.

Product Design & Development

Bringing Your Bold Ideas to Market

Our Capabilities

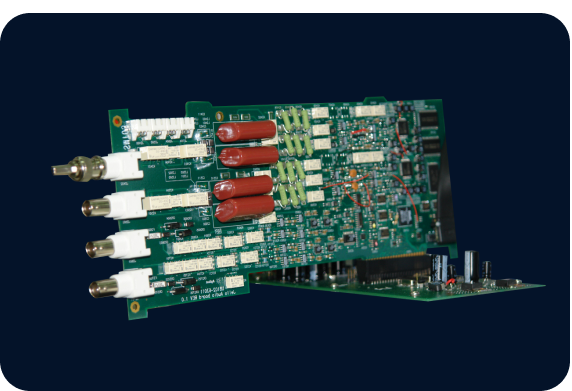

Electronics Hardware Design

- Analog, digital, measurement signal generation & analysis, networking and high-speed digital communications

- Schematics capture

- Printed circuit board (PCB) layout

- Components selection and qualification

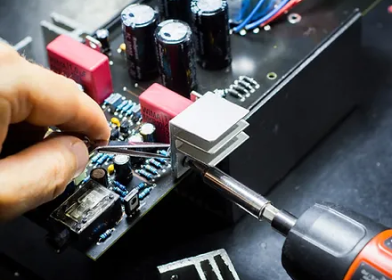

- Design prototype fabrication

- Design verification

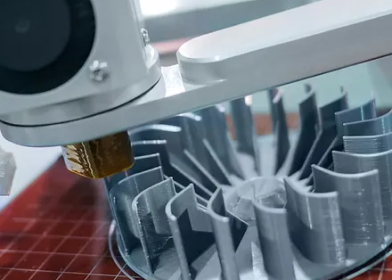

Mechanical Design

- Metal and plastic casing and structure design

- 3D drawing

- Rapid prototyping

- Tooling

- First article build

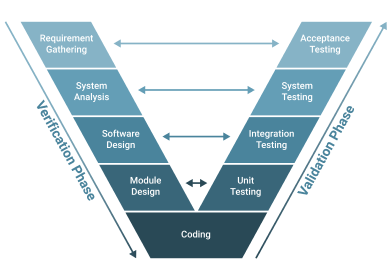

Design Validation

- Validate design against customer requirements based on functionality, usability, reliability, performance and supportability.

- Hardware qualification – ensures product features, functionality and performance complies with customer requirements.

- Software qualification – ensures software design and performance complies with customer requirements.

Process We Follow

Conceptualization

- Requirement Review

- Concept Validation

- Tool Procurement

- DFMEA

- Quality Check -1

Prototyping

- Prototype Build

- Design Test, Verification & Refinement

- Quality Check – 2

Pre-Production

- Sample Build

- Design Validation

- PFMEA

- MP Flow & Control Plan

- Quality Check – 3

Production

- Production Line

- Setup

- Pilot Run

- Process Study

- Quality Check – 4

Product Launch

Our Featured Projects

Advanced Conveyor

System

Multifunction Test

Instrument

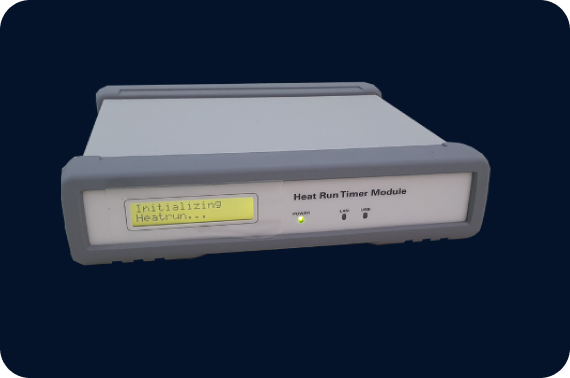

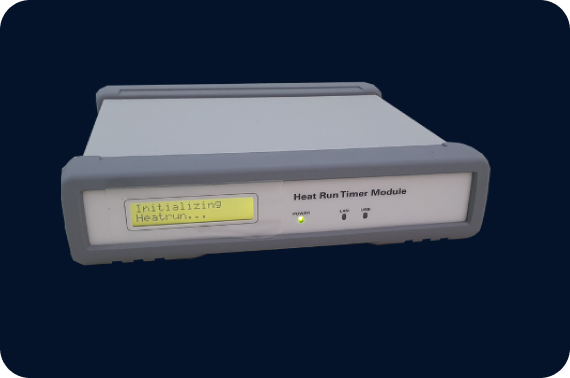

Heat Run Timer

Instrument