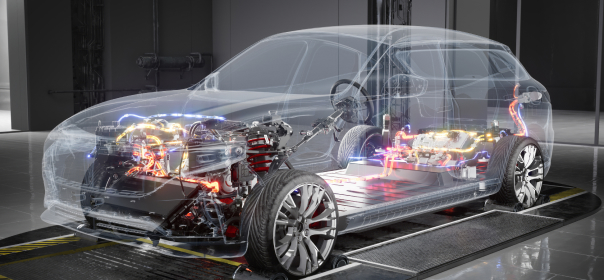

In the crucible of modern manufacturing, the challenges our customer faces are multifaceted. The final verification stage of their manufacturing process, performed by dedicated skilled operators, involves a series of critical calibration tasks – from fine tuning of sensor alignments to manual adjustment of individual tools. This stage is important to ensure precision and product quality; yet, this process is prone to human errors, leading to slower time-to-market, elevated production costs and compromised operational efficiency. To overcome these challenges, the adoption of Smart Factory Automation solution in this process becomes vital.

Smart Factory Automation

The Challenge

The Solution

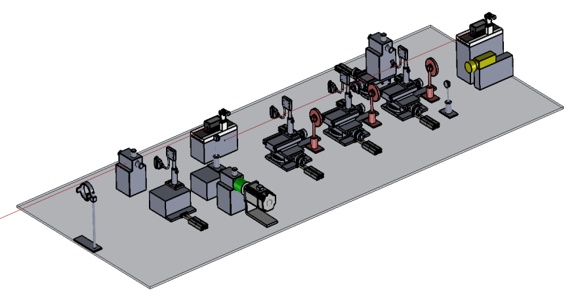

Adoption of Smart Factory Automation by integrating advanced technologies and systems to streamline the manufacturing process and reduce reliance on human intervention. It’s a framework designed to ensure quality control is seamlessly integrated into the heart of production leading to operational optimization. Here are the core elements of this transformative solution:

Key Features

Automated fixturing

Automated fixturing for alignment and tuning is a critical aspect of precision manufacturing. It reduces the need for skilled operators to perform manual adjustments, reducing the potential for human errors and increasing production efficiency.

IoT (Internet of Things):

A network of sensors and feedback mechanisms were integrated into the fixturing system to continuously monitor parameters such as alignment, temperature, pressure, and vibration to make real-time adjustments. This data can be used to adjust manufacturing processes, predict maintenance needs, and ensure overall product quality.

Software Integration

The integration of different software systems used in the smart factory facilitates data sharing, communication, and decision-making across various manufacturing stages.

Incorporating these technologies into the above customer’s solution has resulted in faster production cycles, higher product quality, reduced waste, and improved resource utilization. It’s important to note that the implementation of smart factory automation requires careful planning, investment, and expertise to ensure successful integration and optimization of these technologies.